Geocycle Germany

Overview

Geocycle (Germany) is a reliable partner in the field of innovative recycling and recovery solutions for different waste streams and industrial by-products.

Our business approach has a clear focus on markets, customers and the related waste management. We are part of the global Geocycle network of Holcim Ltd. and offer services to establish the circular economy.

With over 30 years of experience, strong partnerships and a solution-driven mindset, we develop sustainable and safe solutions for the waste and recycling industry.

Our Services

• Sustainable waste management

• Documentation of the treatment and recycling process

• On-site consultation

• Support for import and export management, including documentation in accordance with regulations

• High standards in terms of health, safety and environmental protection

• Evaluation, analysis and characterization of waste

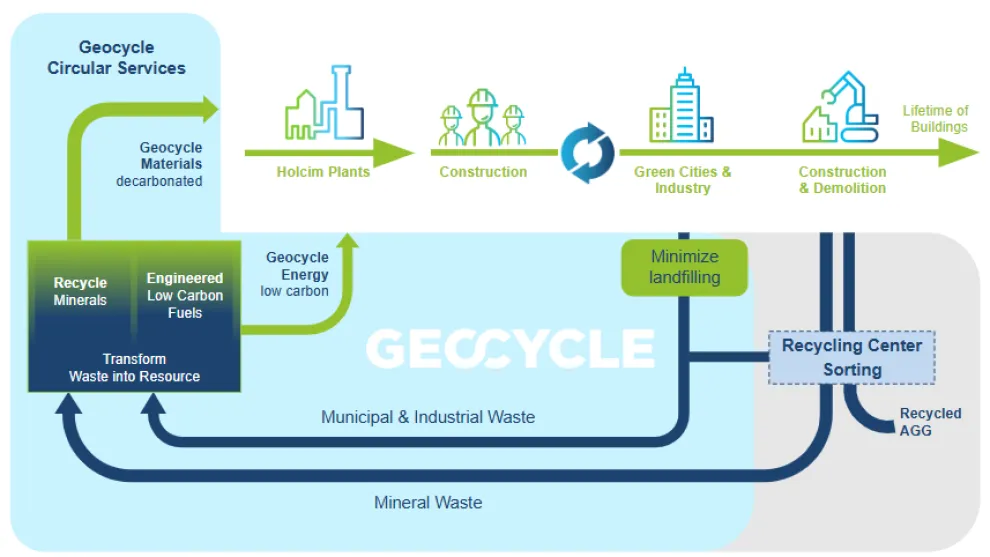

Circular Economy

At Geocycle we reduce emissions in the cement production process and close material cycles along the value chain.

This is possible through co-processing - the simultaneous recycling of minerals and energy recovery within one single industrial process. This replaces virgin raw materials and saves CO2.

Right at the heart of the most important building material for the worlds infrastructure, Geocycle provides a unique service and contributes towards the circular economy.

The waste streams

Geocycle: Expertise at all levels

With our disposal routes, we offer our customers and partners sustainable waste management solutions that represent a preferred alternative to landfill and disposal in the waste hierarchy.

A significant proportion of our partners are waste management companies and industrial companies in the raw materials production, chemical and automotive industries.

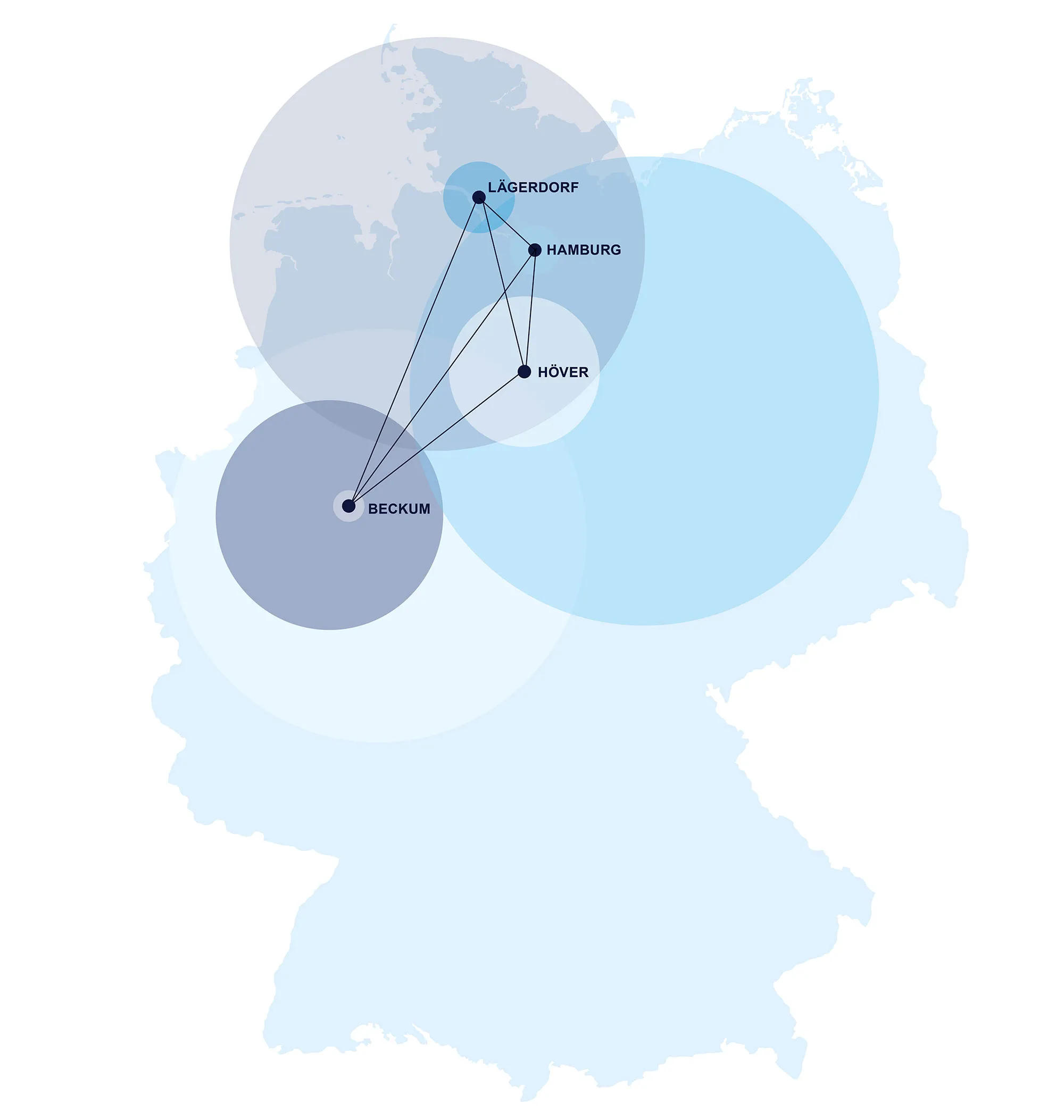

3-plant network: Lägerdorf, Höver, Beckum

We procure more than 800,000 tonnes of alternative raw materials and fuels annually for our three plants in Germany.

A network of three cement plants offers a unique competitive advantage in terms of the geographical range of utilisation options. This network enables flexibility, cost savings and compliance with environmental regulations.

Treatment of hazardous waste:

Utilisation of tarry waste, processed paint sludge and waste oil

We offer the recycling of hazardous waste within our network. This includes waste containing tar, processed paint sludge and waste oil. In this area, we develop innovative solutions together with our customers to ensure the safe and environmentally friendly recycling of hazardous waste.

Processing platform:

Processing industrial waste materials into alternative raw materials

Industrial residues are prepared for use in the cement clinker kiln on our processing platform. Alternative raw materials are created here from various materials, such as residual materials from the steel industry, ash and dust.

Quality control to monitor the composition is a central element in this process. A constant content of the components contributes to the consistently high quality of the cement clinker.

Memberships

Contact

Geocycle Germany office

Geocycle (Deutschland) GmbH

Troplowitzstraße 5

22529 Hamburg

Germany

britta.pfullmann@geocycle.com

+49 40 36002 418