Geocycle Poland

About Us

Geocycle Poland is part of the global Geocycle network and has been in operation in the country since 2001. Thanks to two pre-processing facilities and two kilns in Kujawy and Malogoszcz, we ensure seamless and professional waste management services to our customers. We work closely with our customers to meet their sustainability goals and add value to their business through our tailored processes and in-depth expertise in managing waste. We are partnering with more than 100 customers in Poland and expanding our service footprint. In 2023, Geocycle Poland safely co-processed more than 380,000 tons of pre-treated waste including industrial and municipal waste.

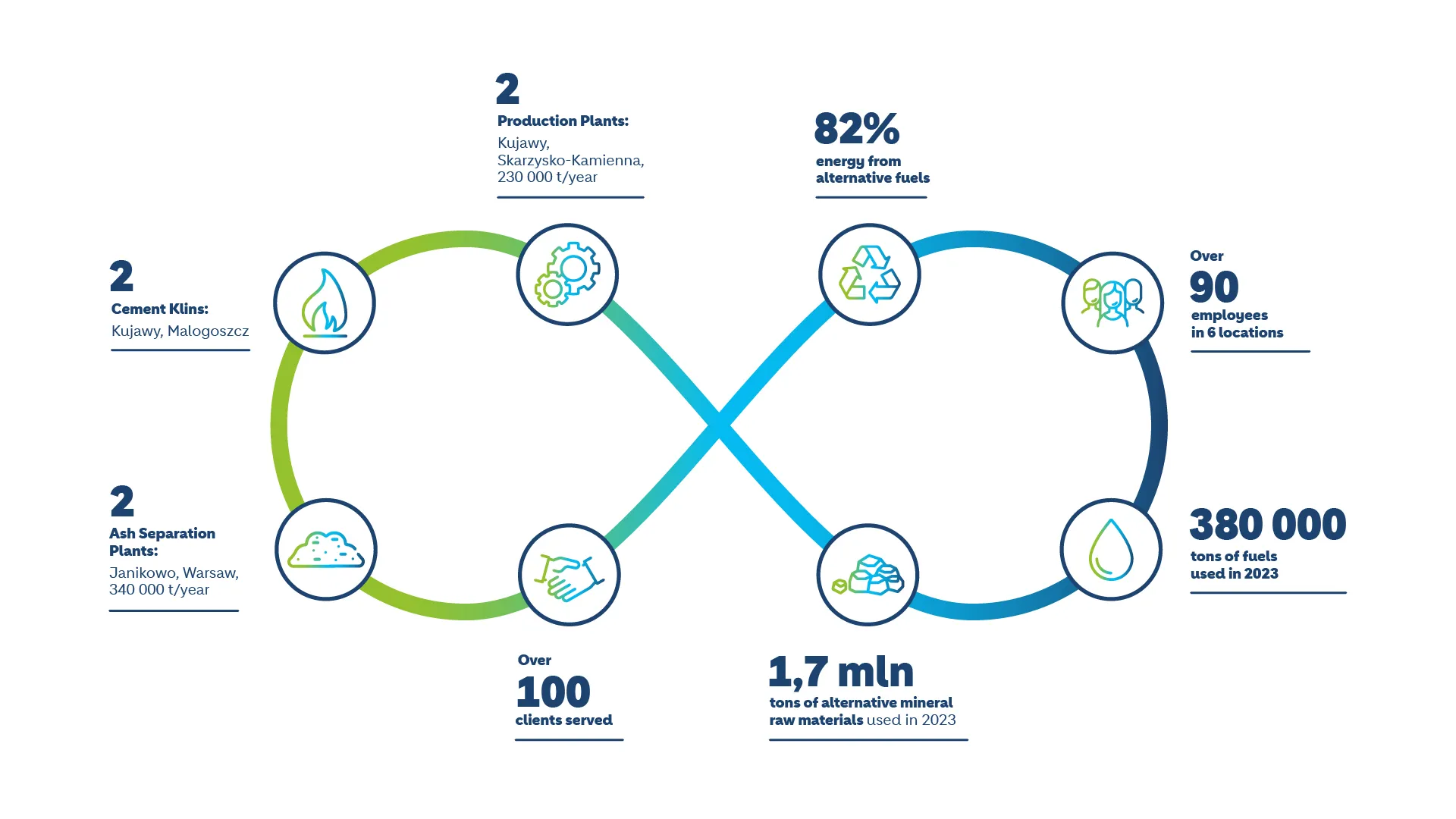

Geocycle in numbers (2023):

• 2 Production Plants: Kujawy, Skarżysko-Kamienna, 230 000 t/year

• 2 Ash Separation Plants: Janikowo, Warsaw, 340 000 t/year

• 2 cement kilns

• Over 100 clients served

• 82% of energy from alternative fuels

• Over 90 employees in 6 locations

• 380 000 tons of fuels used in 2023

• 1.7 million tons of alternative mineral raw materials used in 2023.

Our Services

We provide the following waste services

• Assessment and consultation

• Laboratory analysis and waste characterization

• Logistics

• Transportation

• Waste preparation for co-processing in cement plant

We have the ability to handle a broad variety of waste. We provide a wide range of waste management services, starting from assessment and consultation, laboratory analysis and waste characterization, logistics, transportation and finally waste preparation for co-processing in cement plants. We serve a wide variety of industries. Some of our largest customers are from the paper, foil and textile industry. We help mechanical biological treatment installations by managing the large volumes of sorted municipal waste for which they are seeking solutions. We focus special attention on sustainably managing non-recyclable plastics through our facilities and offer a more sustainable alternative to landfilling or incineration, in line with EU waste treatment principles.

The managed waste streams

SUCCESS STORIES

2024 - New alternative fuel dosing line at the Malogoszcz Cement Plant

As part of the modernization of the Malogoszcz Cement Plant, a new alternative fuel warehouse was built. This project allowed for taking on fuel of two quality categories:

• Burner - alternative solid fuel with high calorific value, prepared mainly from industrial and hazardous waste.

• Precalciner - fuel with lower calorific value, prepared from municipal waste and biomass fuels, which allow for effective management of the decarbonization process.

Warehouses and installations have been equipped with modern fire protection systems. The execution and records of deliveries are digitized and integrated with the Waste Database (BDO). Fuels are dosed automatically and individual streams are adjusted to the energy consumption and CO2 emission rates.

2021 - Third Unloading station with satellite burner

Geocycle Polska supports the production development of the Kujawy Cement Plant with the challenge and requirements of the Group's strategy. The implementation of production and operational goals is carried out using the third unloading station with satellite burner.

Third unloading station with satellite burner allows to decrease the usage of traditional fuels in Kujawy that means less CO2 from coal is emitted to the atmosphere. It may have an important impact on life comfort in the region. Less traditional fuels means more alternative fuels with more effective emission factors can proceed in Kujawy Plant.

Geocycle Polska, based on great experience, connects the expectations of the waste market with the requirements of the cement industry in Poland to reach sustainable strategy and take care of the environment.

Contact Us

Geocycle AFR

Monika Michalska

monika.michalska@geocycle.com

tel +48 519 537 112

Geocycle MIC

Paweł Ludwicki

pawel.ludwicki@geocycle.com

tel +48 784 975 668

Locations