What we do

Our mission is to close the loop by transforming waste into resources on a large scale and promote a sustainable circular economy.

WE TURN waste INTO PROGRESS for people and the planet

As we focus on building a sustainable future for our planet, we are faced with the global trends of a growing population and rising urbanization. These trends accentuate today’s global challenges – from climate change to resource scarcity and waste issues. Awareness of environmental issues is equally on the rise, and with landfill contributing to 5% of our world’s total greenhouse gas emissions, the time to act is now.

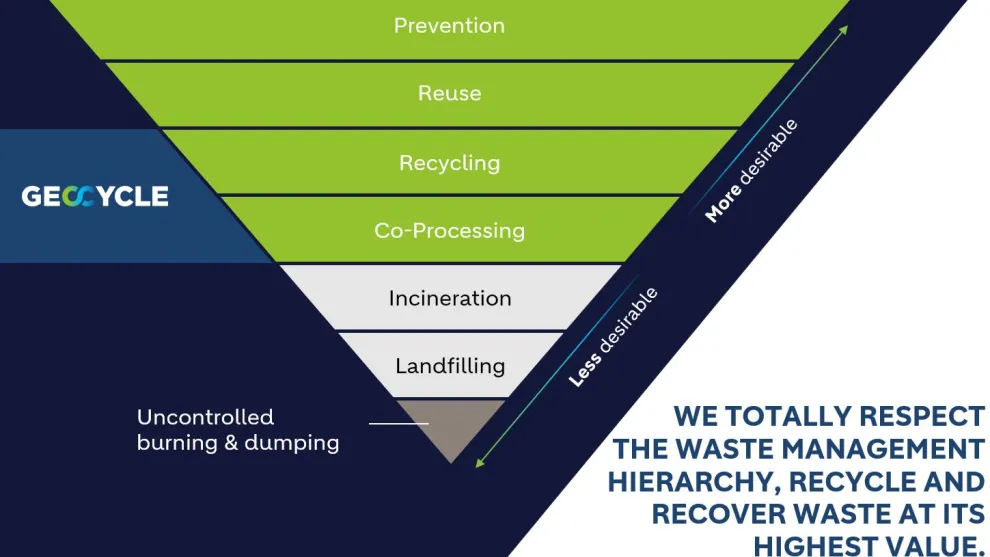

To address these challenges, Geocycle provides sustainable waste management solutions to benefit people and the planet. Waste management is critical to building a sustainable future.

To achieve this, we focus on:

- Reducing natural resource consumption and carbon emissions

- Recycling materials

- Recovering non-recyclable waste

We foster industrial symbiosis and provide highly compliant, economical and practical solutions that give our customers and partners peace of mind on our common journey towards sustainability.

We also actively engage with local communities to understand their needs and support their goals. Through this collaboration, we can ensure our actions resonate with global needs and foster positive change worldwide.